7.3 Power Stroke Engines

7.3 Power Stroke Engines

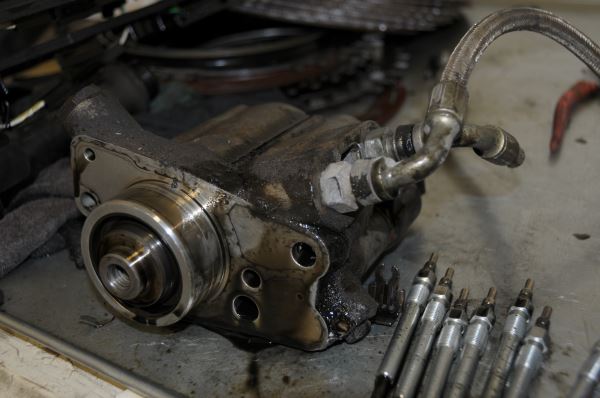

The introduction of the 7.3L Power Stroke included the use of direct injection, which utilizes high-pressure oil as the propelling catalyst and converts it to 4000psi pressure to fire the injectors.

"While this system is generally reliable, any oiling issues can mean bad news for the system," said Lind.

Some of the things Lind suggests that owners look for include fuel floating on the coolant in the expansion bottle. This situation indicates that there is a failed injector sleeve. The next thing to do is look for oil in the engine valley. Often times, the oil seeps down at the back of the block, between the block and bell housing. In most cases, this looks suspiciously like a leaking main seal, but Lind says this list of common culprits is more likely the case and can include a leaking ICP sensor, oil filter housing, fuel filter housing, drain valve assembly, turbo pedestal, warm-up valve, oil feed lines or leaking fuel hard lines.

Although there is a seemingly long list of components to check, Lind says that most of these are easily fixed and can be dealt with in a day. Lind continues his checklist of common 7.3L failures with a dusted engine and damaged turbo. Early Power Strokes had notoriously bad air cleaners and would allow dust through. This dust had a tendency to erode turbo blades, destroy rings and drop compression. This may not completely destroy the system, but can eventually cause serious harm and should be checked from time to time.

.JPG_600.jpg)

While the e40D/4r100 transmission configuration is generally solid, Lind has found they struggle to tow heavy loads up hills over time and can suffer from oiling issues, which may starve the converter in extended high RPM/high load situations. While this may be a little expensive to fix, a proper transmission rebuild, including a few oiling modifications, can rectify the problem and keep that Ford on the road doing what it was meant to do. Lind wraps up the oiling system by reinforcing the importance of regular oil changes. Keeping the oil fresh and clean is the best way to avoid a lot of problems further down the road.

Lastly, Lind advises a checkup on the front suspension every once in a while. The four-wheel-drive diesels will wear out ball joints and tie rod ends every 60-100k miles, and examining these for any problems early on will ensure safe operation in the future.