Rounding It Out

There’s more to this beast than simply a big footprint. Clayton says, “I’ve got an AFE Blade Runner intercooler, all Pusher intake tube and manifold and intercooler piping, and an AFE exhaust manifold. I got it tuned by PPEI and it’s running on a 150hp tune right now. It’s got a FASS Fuel system and an S&B cold air intake. I’m actually building an exhaust for it right now, one that I don’t think anyone else has done. I’m running a 5-inch turbo downpipe to an 8-inch straight pipe all the way up to a custom-made stack with an 8-inch inlet and a 10-inch outlet. Everybody either has a 4- or 5-inch, so I just wanted to be different. I figured it would give it a different tone, and I was getting a custom-made stack anyway, so I thought, why not just go 8 inches and be completely ridiculous?”

He always wanted to have a set of American Force wheels, so he decided to go with some 2-piece wheels. “For mounting the tires on them, you don’t have to try to force the tire over the rim,” he says. “You can just bolt the rim together, so that makes it nice. I just liked the way the two-piece looked with the bolts; I could accent them a little bit and just make it stand out a little better.” For tires, he went with Rolling Big Power 40-inch Repulsor MTs. Other additions include a Horn Blasters triple-horn setup, AMP Research XL Power Steps (“You need something to get in the dang thing. There’s no way I could get in there without something like that!”), an SSK style functioning ram air hood, Oracle rock lights and LED Concepts halos and turn signals.

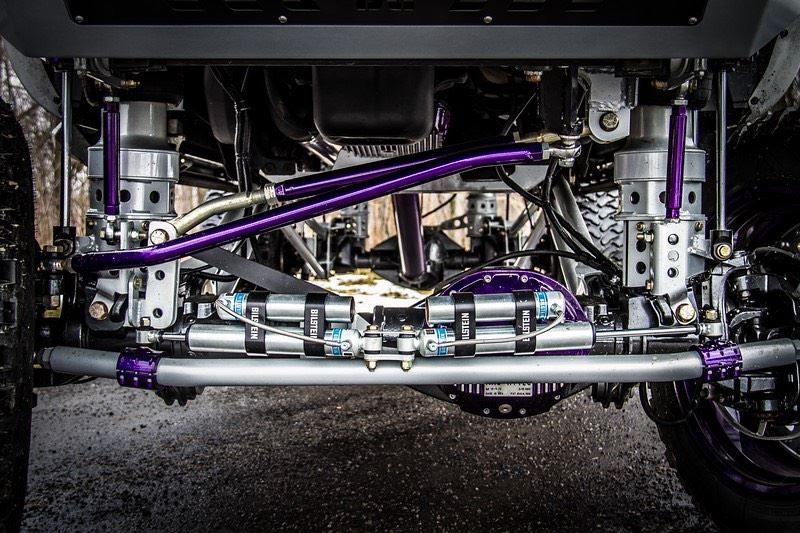

Other additions include front and rear Bodyguard bumpers, Recon tail lights, a Gravel Empire grille and tailgate emblem, an Accuair air management system, R1 Concepts brakes and rotors, True Spike lug nuts, Mag-Hytec front and rear diff covers and transmission pan, F-O-A shocks, 4.56 nitro gears in the axles, and Auto Meter gauges, including a triple pillar gauge. All of the powder coating was done by Totally Baked Powder Coating in Freedom, PA.

He says definitely the hardest thing was trying to get the axles to fit. He got them powder coated and getting them under the truck without scratching them was really hard. “I don’t have a two-post lift, so I had to use a lot of wooden blocks and jack stands. It was not a very fun time!”

He embarked on this crazy journey last February and aside from a few friends helping him out and holding things up while he bolted them on, it’s been a largely solo endeavor for Clayton. “It’s been nuts!” He had some people reach out to him last year about taking the truck to SEMA, but it all happened the week before the show and by then it was impossible. Now that the build is complete, he’s on the hunt for a SEMA spot this year. With the hard work he’s put in so far, we have no doubt he’ll make the grade.