This article originally appeared in the March 2017 issue. For part 1 of this build, click here.

The Environmental Protection Agency (EPA) went on the attack nearly a decade ago by hamstringing auto manufacturers and forcing them to comply with stricter emission standards starting with all 2008 models going forward. Aftermarket companies thrived for years with “deletes” to work around these new restrictions, but eventually the government put an end to this or at least drastically slowed it down.

For those not wanting better fuel economy or improved horsepower, it was easy to keep trucks emissions-equipped, but in reality that’s not what most diesel truck owners want. Is it possible to build a 700hp truck and still keep all of your emissions equipment? When we first started our latest project truck we weren’t really sure, yet still wanted to try because this is where our industry needs to be heading. Fighting the EPA is a battle no one will ever win.

Part 1 Recap

In the first part of this build series Matt Rosenberg, owner of Rosenberg Automotive in southeast Idaho and the owner of the 2016 LML Duramax, laid the groundwork to get us started. Before touching anything on it, the truck sat at 347hp with 511 lb/ft of torque.

Upgrades included a FASS 150 lift pump, Edge CTS 2 and BDS RECOIL traction bars.

Road Trip

In order to take this LML where we need it to go, we called in reinforcements. Wehrli Custom Fabrication in Sycamore, Ill., has earned a solid reputation in the industry as the go-to shop for innovation and custom fabrication work thanks to owner Jason Wehrli and his brother Ryan, who is the head of the fab department. We dropped the truck off to the brothers with more questions than answers and trusted in their expertise.

“We’ll see,” was the response Matt received when talking to Jason after reiterating his goal of getting his emissions-equipped truck to reach the 700hp mark. At this point it hadn’t been successfully done before, so Jason admits he was a little bit worried about this project.

Matt, however, was not. “I knew who I had in my corner,” recalls Matt. “So I got a lot of good sleep knowing my truck was in good hands.”

Redemption

This wouldn’t be the first time Jason attempted something like this. He first worked on an emissions-equipped Duramax build back in 2013 together with his friend Nick Priegnitz, owner of Duramaxtuner in nearby Marengo, Ill.

“Jason and I did a similar project on my own personal LML and when Matt called me it felt like a chance for redemption,” says Nick. “I went for 700hp on an emissions-equipped truck and I fell short at 640hp, so that’s always kind of haunted me. I was excited to get back in the twin turbo game with this truck and tackle the question that’s on everybody’s mind: ‘What’s the limit with a factory emissions system?’”

SunCoast

Before getting to the twins, the transmission needed to be rebuilt to make sure it could hold the power when our build was done. To ensure we wouldn’t have any issues, we reached out to SunCoast Diesel Transmissions.

SunCoast started with a quest to answer the demand for quality aftermarket torque converters, transmissions and parts. Since then the Florida-based manufacturer has identified and corrected failure points within numerous OEM transmissions and torque converters. SunCoast formulates test data using real-world scenarios, along with the latest technology and design methods, to manufacture parts that correct the cause of these failures.

Using the SunCoast kit, the guys at Wehrli rebuilt the transmission, but there was still plenty more work to do before getting to the twin turbos. For injectors we contacted S&S Diesel Motorsport and owner Greg Spoolstra recommended the 60 percent over injectors to help us reach our lofty goals. We also included its CP3 10mm conversion stroker pump, which was a must for this project.

Stuff It?

The hardest part of the entire project for Wehrli Custom Fab was working with the size restrictions of the engine compartment.

“It was frustrating at times since we had a lot of stuff to fit into a very small location,” recalls Jason. “There was a lot of trial and error. We had to scratch our heads a couple of times and go back to the drawing board.”

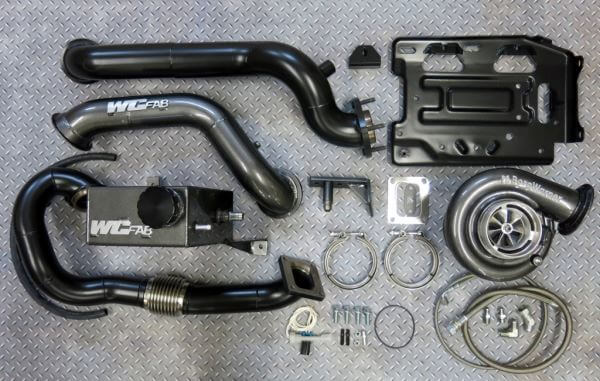

The questions Jason and his brother Ryan needed to figure out were where to put the turbo, how to mount it and where to put all the pipes. A lot of brainstorming and a lot of ideas all came together and after a couple of different attempts and rebuilds, the fab shop was able to come up with a bolt-on compound turbo kit with working emissions that was also compact and still able to fit under the hood.

Downsizing

“Anyone who looks under the hood might think it would be impossible to add another turbo without removing some of the components, but we made it happen,” says Jason.

“Because of room constraints we went down a size to the S300 frame turbocharger, with some special modifications to it. It’s not your typical S475 mainly because of the size and because we had less room to work with and had to go a little smaller.”

To come up with some extra room, the bulky factory cooling tank had to go. The shop rebuilt and fabricated a coolant tank that is a touch smaller—they estimated maybe a quart smaller as far as capacity goes—and allowed them enough room to get the turbocharger squeezed in along with the OEM factory air intake box, as well as all the EGR components, factory battery and all the factory battery cables.

Learning Process

Getting the ninth injector to work in the down pipe and having a good solid connection at the exhaust system was a problem they ran into two and half years earlier with their first attempt.

“It’s really important to have a good solid connection because of that ninth injector that is spraying fuel in there, plus the pressure in those pipes, so we re-used a lot of the GM design work,” says Jason. “We’re not smarter than GM and there’s no reason we need to pretend we are, so we re-used as much as we could of their design. The toughest part was to get everything to fit and not interfere with everything else. It was very tight and we didn’t take a lot off the truck to get it to work. It ended up being a really nice finished product that looks factory. If we powder-coated it black you’d hardly notice there was another turbo there.”

Fine Tuning

Now completely satisfied with how the kit turned out on the emissions-equipped truck, it was all up to Nick and the guys at Calibrated Power Solutions (home to Duramaxtuner.com) to get this truck where it needed to be and build a tune for it.

“When it showed up on my doorstep I was amazed Wehrli was able to get all that stuff in there,” recalls Nick. “The biggest challenge on our end was matching the new air flow situation to the substantially larger, 60 percent over injectors without upsetting the emissions equipment on the truck. There’s a very small window of error; managing those injectors under hard throttle to minimize smoke out was a big challenge.”

With a goal of 700hp Nick knew he had to manage the air/fuel ratio, he had to manage the EGTs, he needed to manage opacity and smoke output while balancing drivability. That’s a lot to ask but he was up for the challenge.

“I had a truck with aftermarket injectors in it, an aftermarket pump, and a twin turbo kit with a DPF on it. So I basically had a smoke-making machine with a smoke catcher on the back of it,” says Nick with a smile. “I was very concerned about the particulate output and very concerned that I didn’t hurt this thing as I’m going through the tuning process, so I had to start small.”

Calibrating

In the first week Nick estimates he got the truck to about 80 percent of where he wanted it to be. From there he just needed to do a little polishing.

“It’s called calibrating for a reason and we literally needed to dial it in,” says Nick. “Bob Peterson did a lot of that work too so he deserves some of the credit. We needed to trim off the fat wherever we were going to see extra smoke, where we’re going to see air/flow ratio dips, adjusting the shift points, so the driver can do whatever he wants with the throttle. “In the truck responded great with zero smoke output.”

Nick also credits S&S Diesel Motorsport for helping with the injector calibration.

“Those guys went through and fully calibrated the injector set and by doing that they allowed me to know how much fuel I was injecting into the truck and once I knew that I could use the mass air flow rate and understand how much air flow I need in order to control smoke.”

The Results

Bob fired the truck up with it strapped on the Duramaxtuner dyno, as it was now time to measure the success of the build, at least from a numbers standpoint. The truck now sits at an impressive 733hp and 1338 lb/ft of torque, proving 700hp is in reach for an emissions-equipped truck with the right team involved. However, the real test came when the truck hit the open road and began the 1500-plus-mile journey back to Idaho. Both Nick and Jason were confident the trip back would be a success since they had each already put a lot of seat time in making sure there would be no issues and we’re impressed by their own experiences.

“The truck acts very stock. It acts like one of our tuned LML trucks,” explains Nick. “It’s quiet and you can barely hear the big turbocharger but when you lay into this thing it’s responsive. It takes off, zero smoke and it’s mean and it wants to go. It turns the tires over hard. You’re talking 1300 pound-feet of torque, so it’s up there. It wants to eat the tires off and the coolest part in my opinion is the EGTs. Anyone can make horsepower, but it’s about maintaining your fuel ratio and controlling EGTs and even at the power levels we’re at we’re 1250, 1270, barely over 1300 degrees and that’s at triple-digit speeds.

“Jason adds that the Borg Warner S369 SXE model is a very popular turbo that we sell a ton of in single applications. Who would have thought it was something that was going to work in a compound application? It comes to life before you can even think about it. Five or six pounds on the boost gauge and that charger is ready to rip. It goes and it pulls all the way through and is a blast to drive.”

Moving forward

With our goal of 700hp now met, the story doesn’t end here. The Ultimate Callout Challenge is on the horizon and this LML is ready to compete in the emissions-equipped category.

“I’ll step up to whatever is put in front of me,” says Matt. “I’m looking forward to getting out and showing people what this truck can really do.”

Adds Nick, “There’s a chart of benefits to deleting and benefits to keeping emissions equipment and we keep crossing those lines off in the delete column. Better EGT control? I think we crossed that off today. The ability to make over 700hp? We crossed that off today. The smoke output, the quietness, the case is there. The decision to delete is not as easy in my book as it was.”

We couldn’t have said it better ourselves. Here’s to the future of diesel performance!

Nick Priegnitz, Austin Carlisle, Bob Peterson, Matt Rosenberg and Jason Wehrli were all instrumental in getting this LML where it is today.

Sources

BDS Suspension

517-279-2135

www.bds-suspension.com

Big O Tires

866-834-2652

www.bigotires.com

Curt Manufacturing

800-738-7213

www.curtmfg.com

Duramax Tuner

815-568-7922

www.duramaxtuner.com

Edge Products

888-360-3343

www.edgeproducts.com

Empire Covers

888-872-6855

www.empirecovers.com

FASS

866-769-3747

www.fassride.com

Moto Metal Wheels

562-921-1237

www.motometalwheels.com

Rosenberg Automotive

208-754-8600

S&B Filters

800-358-2639

www.sbfilters.com

S&S Diesel Motorsport

810-869-4247

www.ssdiesel.net

Smith Chevrolet

208-522-9800

www.smithchevy.net

SunCoast Diesel Transmissions

850-864-2361

www.suncoastdiesel.com

T-REX Grilles

951-270-5388

www.trexbillet.com

TruXedo Bed Truck Covers

877-878-9336

www.truxedo.com

Ultimate Callout Challenge

www.ultimatecalloutchallenge.com

Wehrli Custom Fabrication

630-277-8239

www.wcfab.com