Here we are driving down the road in Atlanta, Ga., during rush hour traffic when out of nowhere the truck starts to shake and jerk and no longer wants to go. We make it across several lanes of traffic to the emergency lane and come to a stop. With the hazards on we get out of the truck and see transmission fluid dripping on the ground. Great, I think to myself. How could the trans be bad after just over 2K miles? And wouldn’t you know it? That’s just about how far from home we are.

Here we are driving down the road in Atlanta, Ga., during rush hour traffic when out of nowhere the truck starts to shake and jerk and no longer wants to go. We make it across several lanes of traffic to the emergency lane and come to a stop. With the hazards on we get out of the truck and see transmission fluid dripping on the ground. Great, I think to myself. How could the trans be bad after just over 2K miles? And wouldn’t you know it? That’s just about how far from home we are.

So we try waiting to see if it was just too hot and after about an hour of cooling we start the truck and try to drive but we’ve got nothing. No forward, no reverse, nothing—the transmission is gone!

Why is it so hard to find someone that can build a transmission that will not only get you where you need to go, but back as well? After spending thousands of dollars to have the truck repaired in Atlanta so it could make the trip back home, it was time to talk to Ultimate Transmission so we could have a dependable truck could travel all over the country with any kind of load and be the truck we know will make it.

Well Tested

When it comes to project LBMC, we have tested this truck beyond what most people would ever think of doing to it. Trial and error, broken part after broken part, we wanted to make this a truck that would truly be the ultimate tow rig.

After a few too many transmissions, it was time to get serious about this next transmission build. That’s why Ultimate Transmission out of Garden City, Idaho, was the only choice for us. We were so sick of being stranded because of transmission problems and fine print warranties that it was time to make this thing reliable. We contacted Ultimate Transmission and discussed all the details about what the truck was used for and how we wanted to be able to go anywhere in the country AND make it home under its own power. Unlike others who say that you can’t have your cake and eat it too, Dave Fleenor and Matt Hiscox both assured us that unlike other companies who build transmissions as if they are on an assembly line (where potential problems can be overlooked), their transmissions are built one at a time and built to hold up to the kind of driving conditions we put project LBMC through. So after discussing the rigorous beating this thing has to take and what this truck was used for, we dropped the truck off at UT to get started on LBMC’s ultimate transmission. When we arrived at UT we were greeted with a hand shake. It was nice to be somewhere that cared about making a great first impression and not just a, “How can we help you?” attitude, the kind of place that makes you feel as if you are the one that needs help. We talked about what parts would be used and how those parts were going to make this the transmission that would make LBMC finally able to haul heavy loads across the country and make it a reliable truck again. After pulling the truck in and getting on the hoist, it was time to get started. First things first: pull the old transmission out and tear it down.

Removal, Inspection And Surprises

After removing the drive shafts, transfer case, cross members, wiring, shift cable and transmission cooler lines, the transmission was ready to separate from the engine like so many times before. After separating the two, and getting a good look at the flex plate, we noticed that the holes for the torque converter bolts  and the center hole

and the center hole  for the converter hub were oblong and no longer round. If the torque converter is not perfectly centered with the crankshaft it will not spin smoothly. Instead, it spins in an off-centered pattern that not only causes vibration, but may also cause a transmission to fail long before its time.

for the converter hub were oblong and no longer round. If the torque converter is not perfectly centered with the crankshaft it will not spin smoothly. Instead, it spins in an off-centered pattern that not only causes vibration, but may also cause a transmission to fail long before its time.

Needless to say, whenever you change the transmission in anything, always check everything for wear, leaks, or potential problems. Rear main seals, wiring, shift cables, oil lines, mating surfaces, flex plate/ flywheel, bolt holes, and anything else that could be problematic. There’s no reason any of these things can’t be repaired while the transmission is out of the way.

Continuing the inspection of all the accessible components with the transmission out, we not only found that the flex plate was bad, but one of the cooler lines was about to blow apart , a bolt had been cross-threaded, a few more had been stripped out and there was even one broken bolt in the cross member that holds the skid plate up

, a bolt had been cross-threaded, a few more had been stripped out and there was even one broken bolt in the cross member that holds the skid plate up  .

.

Not Fixed Earlier?

And to think that all of these things were going bad, or screwed up when the transmission was put in the last time. Why wouldn’t a shop check these things for damage, wear, or improper fit? Why were stripped, cross-threaded, and broken bolts not fixed? Maybe things like this would void that fine print warranty? Who knows why they were not taken care of properly before they became more of a problem? After making a list of the parts that needed to be replaced or repaired, the new parts were ordered and the tear down of the transmission was started.

Trans Inspection

After the tear down was complete, the case and all parts were put into a hot wash tank to be cleaned. When the parts are cleaned, Fleenor and his crew begin their inspection to check for imperfections, wear or damage. All piston bores are checked for scratches, scuffs and cracks . If any are found they hone the case to assure a leak-free seal

. If any are found they hone the case to assure a leak-free seal . All oil passages are pressure checked, and mating surfaces where valve body and the transmission pump attaches are also inspected. On a performance build much stronger than stock parts are a must, especially when you are running the amount of horsepower and torque that most performance diesel trucks run with aftermarket modifications like LBMC.

. All oil passages are pressure checked, and mating surfaces where valve body and the transmission pump attaches are also inspected. On a performance build much stronger than stock parts are a must, especially when you are running the amount of horsepower and torque that most performance diesel trucks run with aftermarket modifications like LBMC.

Performance Goodies

The input shaft is upgraded from a “necked down” 23 spline shaft to the Ultimate proprietary billet steel input shaft—which is a larger, custom 35-spline two-piece design that requires a custom torque converter and was found to be stronger than the one-piece design.

The 23-spline, two-piece shaft on the top and the 35-spline two-piece shaft on the bottom.

The 23-spline, two-piece shaft on the top and the 35-spline two-piece shaft on the bottom.

The Intermediate shaft is also replaced with a larger billet shaft. The stock 23-spline tail shaft is improved to a proprietary billet 29-spline shaft that increases strength by 20 percent plus over a 23-spline billet shaft.

The 29-spline shaft on the left, 23-spline on the right.

The 29-spline shaft on the left, 23-spline on the right.

This modification requires the input shaft on the transfer case to be enlarged to a 29-spline shaft, the same input shaft that is used on manual transmissions.

Stock 23-spline shafts on the left, 29-spline shafts on the right. Top two are transmission tail shafts. Bottom shafts are transfer case input shafts. This 29-spline input shaft is for the NP241 transfer case, which is used with the custom 29-spline tail shaft.

Stock 23-spline shafts on the left, 29-spline shafts on the right. Top two are transmission tail shafts. Bottom shafts are transfer case input shafts. This 29-spline input shaft is for the NP241 transfer case, which is used with the custom 29-spline tail shaft.

The larger 29-spline input shaft is used with standard transmissions. The stock shafts are on the left. It’s easy to see the difference in diameter of the shafts, which are significantly increased with the 29-spline Ultimate input shafts.

The planetary gear housings that get used are fully-welded instead of the spot/tack welded style that are used in stock transmissions

Planetary gear housings, the stock ones on the right, only have a few welds that hold them together. The fully-welded housings on the left are the ones that are made and used by Ultimate Transmission. Notice the top left housing has a recess machined into the middle of it. That is to allow for thrust bearings instead of thrust washers.

Planetary gear housings, the stock ones on the right, only have a few welds that hold them together. The fully-welded housings on the left are the ones that are made and used by Ultimate Transmission. Notice the top left housing has a recess machined into the middle of it. That is to allow for thrust bearings instead of thrust washers.

Yet another impressive feature to be found on this build was the deeper direct clutch hub, which allows for an extra clutch and steel to engage. Normal clutch hubs would drop the last clutch. They use a proprietary aluminum alloy that is as difficult to cut as steel. It is a billet aluminum versus the cast aluminum used on stock. Another alternative being used by competitors is to anodize the finish on cheaper aluminum to achieve a surface tension that may hold up. Ultimate Transmission uses the better aluminum so they know it will hold up. Simply put, better materials, better transmissions!

On the forward clutch drum oil feed, the factory uses barbaric plunge cuts for oiling. Ultimate Transmission uses billet drums with machined ports that are more efficient and provide oil flow to the piston.

Billet drum on the right and the stock drum on the left.

Billet drum on the right and the stock drum on the left.

This creates a smoother radius for better connection with far less cavitation, and provides a more fluvial oil flow for more even clutch engagement.

UT billet drum with machined oil passages and 9892 stock plunge cut drum.

UT billet drum with machined oil passages and 9892 stock plunge cut drum.

After all of the internal parts of the transmission are assembled, checked for proper spacing, and put into the case, the oil passages are filled with transmission fluid and pressurized with air to check for proper engagement and seal of all clutches and bands.

Checking clutches and band engagement with air.

Checking clutches and band engagement with air.

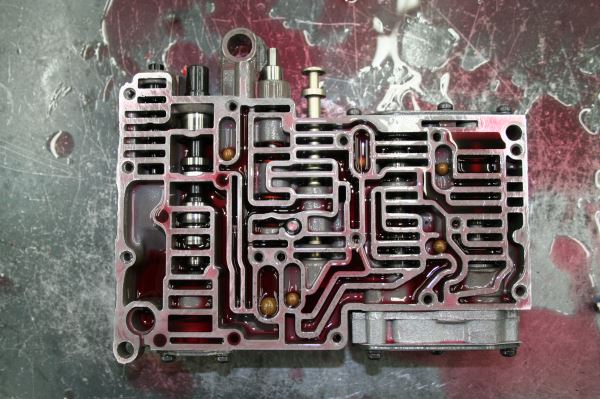

High resin is used for the holding clutches and carbon Kevlar hybrid is used for shifting clutches, increasing the holding capacity over stock clutches. Valve body is disassembled and inspected. Depending upon the shifting firmness that is desired, oil passages can be enlarged to allow more fluid to different areas of the transmission for firmer engagement of the clutch and or band.

Inside view of the valve body and check balls.

Inside view of the valve body and check balls.

When the valve body is thoroughly checked and the proper modifications are made, it will assure the desired firmness of shifts will be achieved. The valve body is then tested to ensure that all components are functioning properly before being put on the transmission.

The transmission has been assembled and tested with oil/air.

The transmission has been assembled and tested with oil/air.

Transmission with the valve body installed.

Transmission with the valve body installed.

All bolts are hand-torqued to the proper specs using a torque wrench and the torque converter is pre-filled with transmission fluid and installed onto the input shaft of the transmission.

The torque converter being filled with oil.

The torque converter being filled with oil.

The torque converter installed on the input shaft.

The torque converter installed on the input shaft.

Ultimate Transmission has custom torque converters made just for their transmissions that come in a wide variety of stalls and can be made to order from stock to extreme.

Transfer Case Inspection

The input shaft on the transfer case has to be replaced with a 29-spline shaft. The stock shaft is a 23-spline for the automatic transmission truck and a 29-spline for the manual transmission truck. Some transmission shops simply take the 23-spline input shaft out of the transfer case and machine a slot across it to accept their “plug welded” transmission tail shaft.

The stock transfer case input shafts. The one on the right is a “modified” shaft.

The stock transfer case input shafts. The one on the right is a “modified” shaft.

This is a cheap way to try and make the tail shaft of the transmission stronger, but ultimately it is nowhere as strong as the proprietary billet 29-spline shaft that Ultimate Transmission uses. When we disassembled the transfer case we found that one of the thrust bushings on the shift fork was not installed properly and needed to be replaced.

Thrust bushing on shift fork is out of place and could have ground into the slider and caused a catastrophic failure in the transfer case.

Thrust bushing on shift fork is out of place and could have ground into the slider and caused a catastrophic failure in the transfer case.

The shift fork bushing out of the transfer case.

The shift fork bushing out of the transfer case.

Once the transfer case is disassembled, it’s off to the parts washer . After a good cleaning, the transfer case parts get inspected then prepped for reassembly. All new bearings and seals are used along with the 29-spline input shaft for the manual transmission trucks.

. After a good cleaning, the transfer case parts get inspected then prepped for reassembly. All new bearings and seals are used along with the 29-spline input shaft for the manual transmission trucks.

New bearing installed into the 29-spline input shaft.

New bearing installed into the 29-spline input shaft.

The components of the transfer case are carefully put together and checked for proper thrust clearances.

Transfer case assembly.

Transfer case assembly.

The new 29-spline input shaft installed and transfer case with the stock 23-spline shaft below it.

The new 29-spline input shaft installed and transfer case with the stock 23-spline shaft below it.

All of the stripped/broken bolts were taken care of and the cooler line and flex plate were replaced to assure a trouble-free transmission.

The new flex plate being torqued by Dave Fleenor.

The new flex plate being torqued by Dave Fleenor.

Once everything was repaired or replaced, the transmission was ready to install.

The transmission being installed by Dave Fleenor.

The transmission being installed by Dave Fleenor.

All the bolts are hand-torqued to assure that nothing gets cross-threaded or broken.

All the bolts are hand-torqued to assure that nothing gets cross-threaded or broken.

After all the bolts, cooler lines, wiring, covers, and shift cables are installed, the transfer case is lifted into place and bolted onto the transmission.

The transfer case being installed.

The transfer case being installed.

Drive lines, cross members, skid plate, and wiring is installed on the transfer case; then fluid is added.

The Test Drive

With Fleenor behind the wheel and a few excited passengers, we set out for the test drive. He started off easy to ensure the fluid passages were filled with oil and all air was removed. As we pulled out of the parking lot the transmission seemed to shift perfectly. The truck started out in first gear as it should and made all the proper shifts at the proper times and the lock-up was nice and firm. With a big smile on his face Fleenor continued to drive around Garden City, checking the transmission and transfer case to assure they were functioning the way they should. Next was a freeway run. Under moderate throttle, the transmission felt great and much better than any transmission that this truck has had to date. We couldn’t wait to hook a trailer to it and find out what it would do with a load behind it. Needless to say we were all smiles as Fleenor drove back to the shop, working the throttle more and more.

This was a great test drive; not only was it fun and the truck drove better then ever, it seemed to be getting more power to the ground. When we arrived back at Ultimate Transmission, Fleenor checked all fluids again to make sure everything was good to go

The Ultimate Transmission crew in front of Project LBMC.

The Ultimate Transmission crew in front of Project LBMC.

On our way back to Salt Lake City, Utah, the truck shifted great and we noticed a slight increase in fuel economy and lower transmission temperatures. The transmission has several thousand miles on it and a few trailers have been towed cross country and returned without mishap, unlike the trip to Atlanta where we felt we were doomed to always have our roadside service on speed dial. Thank goodness for Ultimate Transmission for making this a trustworthy hauler again. This was truly a great decision for this project and something we should have done in the first place when adding twin turbos, big injectors and a chip.

One thing that should always be noted is that you most generally get what you pay for. In this case, you will get more than you pay for by far. With a great team to talk to and ask any questions we might have. We have consulted them on several different occasions about our personal trucks and our friends’ trucks. They always make time to help us with the problems we have with transmissions that have yet to be built by Ultimate Transmission.

Ultimate Transmission truly rates better than five stars in our book. We are looking forward to testing this transmission and giving a full report in the future. As for now, we are happy to be using this project to better inform you, the reader, in what works the best and who is the best for building an all-around fun truck, a truck that not only turns heads, but can be put to work towing a load that most other trucks would have to steer clear of. As for project Long Bed Mega Cab, this truck just keeps getting better and better, load after load and mile after mile. All we hope for is that one day we can go to the local Ram dealer and get a truck that is as well-equipped as our LBMC is. Until then, we will continue to test this truck and other products to make one of the best head-turning tow rigs out there. We hope to do a big brake kit and free spine hubs on LBMC in the near future to increase fuel economy and braking.

If you have any ideas or know of any products that would make LBMC a better tow rig, let us know by sending your ideas or the product information for Project LBMC to dteditor@dieseltechmag.com. (Don't forget to specify what project you want to see your ideas or products tested on.)

Ultimate Transmission

220 West 37th Street

Garden City, ID 83714

208-631-2133

www.ultimatetransmission.com